Custom Patches

Customize Your Perfect Patches

Limitless customization options for a patch that’s as unique and imaginative as your brand.

Customizable Patch Types

With a low per-item price, great margins, and endless ustomizability, patches are perfect for fashion brands, companies looking for promotional materials, law enforcement agencies, fire departments, military organizations, and more. Sell them on their own, iron them onto uniforms, adhere them to apparel, or hand them out at trade shows to increase brand awareness.

Use your imagination

Start with the basics: what type of patch you’re looking for and how many you’ll need. Customize every last millimeter of your patch, from the backing to the shape to the materials used.

Give Us the OK

Your patch = your canvas. Upload your own pretty artwork if you have it, or work with one of our pro in-house designers free of charge.We’ll send over a mockup or physical sample of your patch for your approval, then make as many weaks as it takes until you’re 100% satisfied.

Shipping and Receive Your Patches

Mail time! We’ll send your gorgeous patches to your doorstep, with free tracked shipping.

Custom Patches for Every Industry

You’re about to meet your patch. Whether you’re looking to create a custom patch for your scout troop, sports team, apparel brand, or military unit, we’ll help you bring your vision to life.

Motorcycle Patches

You can’t ride a Harley Davidson without a custom motorcycle patch. Explore a plethora of different options to create a one of a kind custom patch that is worthy of the road.

Military Patches

Every custom military patch is made with the deepest respect and gratitude to our service men and women. It doesn’t matter what military branch you belong to, a custom made patch belongs on your uniform.

Sports Patches

Nothing says “team spirit” quite like a custom sports patch. Score a winning custom made patch with a variety of special options to choose from.

BOY SCOUT PATCHES

For over 20 years, Topone Accessories has been privileged to provide millions of Boy Scout Patches throughout the world. We hope to continue to provide you with the highest quality Scout patches at the lowest prices anywhere!

Coffee Patches

Topone embroidered patch, using exquisite embroidery technology, embroidered patch is a perfect clothing personality accessory.You can use these beautiful embroidered patch to cover broken holes or decorating clothinges. Show off the unique of you. Have fun!

Law Enforcement Patches

Iron-On Patches, Apply Using Iron or Heat Press to Denim Jackets, Hooded Sweatshirts and Travel-Bags.Quality Embroidered Patches, Durable, Color-Fast & Suitable for Outdoor Use and Long Sun Exposure.Commonly Used for Motorcycle Leather Vests or Jackets, Riding Gear for Bikers, Travel Bags & Luggage for Touring and Road Trips!

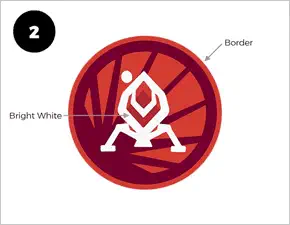

Custom patches we had made for people like you.

Be unique! There are no limitations on what you can do with your custom patch design. Just Imagine it then tell us what you want, we are here if you need help.

Frequently Asked Questions

Most frequent questions and answers

We can make a patch as small as 0.5” (Printed and Woven) but details are subject to assessment as complicated designs may no longer be legible in the final product if the size is too small.

Embroidered Patches: 13” overall size

Woven Patches: 12” overall size

Printed Patches: 18” overall size

PVC Patches: 5” overall size

Leather Patches: 12” overall size

Bullion Patches: 5” overall size

(Height + Width) ÷ 2 = Overall Size.

Embroidered Patches

Embroidered patches work great for uniforms (armed forces, emergency workers, etc.) and as high-end accessories for jackets, caps and bags.

Woven Patches

Woven Patches are perfect giveaways at events. If you are organizing an event, you can have all the volunteers wearing the patches on their uniforms to add a unique touch. They also work well as creative accessories for clothing, denims, caps and bags.

Printed Patches

Printed patches are great for giveaways or light-use situations, where you can convey a lot in a single patch.

Leather Patches

Leather patches are classically applied to jeans and jackets of various kinds to give them an upscale look, but they’re also great for t-shirt pockets, canvas and twill textured products, various head ware, and bags.

PVC Patches

PVC patches are a fantastic option for sports teams, airsoft groups, scout troops… the list goes on! Both versatile and stylish, PVC patches can serve virtually any purpose. PVC patches also ranges from a wide variety of colors and shapes.

Bullion Patches

Bullion patches can be used by anyone, however, some of the most common organizations to use them include:

• Military Branches (Army, Navy, Air Force, Marines, National Guard)

• Sports Clubs • Security Organizations (Police, Fire Services, Building Security, etc.)

• Ancestry Clubs

• Volunteer Organizations

• Private Clubs

• Fraternal Organizations

• And more.

Embroidery patches: These are perfect for uniforms, such as those worn by military personnel, emergency workers, and other organizations. They can also be used as high-end accessories on jackets, hats, and bags.

Chenille patches: These are great for letterman jackets, varsity sports teams, and other athletic organizations, as they add a classic and traditional look.

Bullion patches: These are typically used for military uniforms and formal attire, as they have a luxurious and ornate appearance due to their metallic thread embroidery.

PVC patches: These are ideal for sports teams, airsoft gun groups, and outdoor organizations, as they are durable, weather-resistant, and come in various colors and shapes.

Printed patches: These are suitable for giveaways or promotional events, as they can convey detailed designs and information with high-resolution printing.

Woven patches: These are versatile and can be used for a wide range of purposes, including as promotional items, team uniforms, and event souvenirs.

Leather patches: These are commonly used on denim jackets, jeans, bags, and hats to add a rugged and stylish look. They are also suitable for high-end fashion and accessories.

Of course, many people also use various patches as coasters, as plate pads, as collectible toys, as bookmarks, as clothing patches, as decorations for new clothes, and so on. There are endless uses waiting for us to discover.

All customers will discuss a delivery date with us before placing an order for patches. As long as it's a delivery date we've committed to, we will definitely deliver on time. Generally, for embroidered and printed patches, we can deliver within 3-7 days. For woven and PVC patches, as well as leather patches, we can typically deliver within 5-10 days. If you're not in a rush, please give us a little more time to carefully handle each batch of orders.